TROJAN

Trojan Portable Gas Analyser (PDGA Series)

-

- PDGA

- : Trojan Portable Gas Analyser

Combined with the Morgan Schaffer Calisto 2, 5 or 9, this unique system revolutionises the ease and simplicity of main tank monitoring and condition assessment in real time. The Trojan Calisto provides the transformer manager the opportunity to accurately analyse a large or small fleet of transformers to identify potential trouble units. The Trojan Calisto is a unique and innovative means to apply on-line monitoring to energised transformers for the short term. Operators find these extremely easy to use & a valuable tool in the maintenance program.

Key features – contribution to asset management strategy

A unique and innovative means to apply on-line monitoring to energised transformers for the short term

Qualify main tank fault gas issues online

Find those transformers that require full time monitoring

A persuasively economic and quickly-confi gured method to survey in-service strategic assets

Got a problem transformer? Simply leave the Trojan Calisto attached while a response is planned.

Key features – ease of use

Trailer mounted, small and light

Highly portable and easily positioned in the substation

Safe, easy and quick connection to energised transformers of all sizes / Kv

Safe unattended operation with communication options

Analyse a large number of transformers quickly and accurately

No consultants and expensive specialist installers at each point of use

Use existing operators to relocate the Trojan Calisto

No need to connect into SCADA for data and alarms...unit offers a wireless 'parallel' SCADA option

Key features – online monitoring

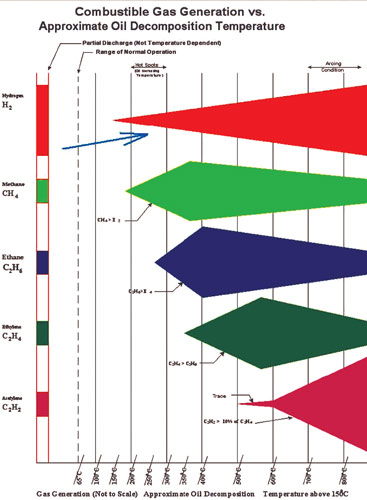

Hydrogen is the key fault gas in all situations

Follow up on traditional DGA lab results to get real online values

Unequalled precision and accuracy facilitates comparison with lab results

No interferences from other gases eliminates false alarms

Continuous oil circulation ensures accurate representative sampling

Short and long term stability facilitates trending

Carbon monoxide values in the oil of free breathing transformers can be quite misleading with traditional DGA sampling

Monitors Hydrogen, carbon monoxide, oil temperature, water in oil for extended long term protection

Operational Benefits

The Trojan Calisto provides the transformer manager the opportunity to accurately analyse a large or small fleet of transformers to identify potential trouble units. The historical DGA profi le gained from oil samples may indicate potential problems, but can be equally misleading. One oil sample taken at any given moment in time does not necessarily refl ect the true condition in the transformer at that point in the load cycle. If a potential fault gas is detected, continuous re-sampling is both time consuming, expensive and prone to inaccuracy. The trailer mounted Trojan Calisto provides online real time accurate key gas data of all faults. If a transformer is suspect, simply connect the Trojan Calisto while the transformer remains energised and leave unattended. If the key gases increase beyond pre-set values the system will automatically communicate immediately.

The Trojan Calisto provides a simple, accurate alternative to the annual oil sample gathering for DGA analysis.

Trojan Calisto Operating Cycles

Automated Commissioning cycle – employs the Trojan Systems proven, safe and fully automated commissioning cycle that removes all air from the system. PLC screen prompting advises the operator throughout the process, and makes the system ready to use within 15 minutes.

Analysis / monitoring Cycle – continuous circulation of the oil from the transformer through the uniquely designed Trojan Calisto tank system allows accurate real time measurement of Hydrogen, Carbon Monoxide, water in oil relative saturation and oil temperature values. This data, along with date and time are recorded to memory for easy access.

Decommissioning Cycle - safely evacuates the oil from the Trojan Calisto back into the transformer prior to disconnection and removal. Again, screen and audible prompting ensures simple and safe operation.

Why monitor hydrogen and carbon monoxide

Most experts will agree that hydrogen is the perfect gas for the early detection of a changing transformer condition. However, repeated overloads or cooling system defi ciencies can also affect the condition of your transformer insulation system, leading to accelerated ageing and degradation of the insulating paper.

Carbon monoxide monitoring is therefore an additional tool that can help transformer specialists assess the remaining life of their transformers.

Detect tank problems and cellulose overheating

Not only is hydrogen present in all transformer faults, it is also the gas appearing fi rst when a problem is developing. This means that detection of hydrogen traces is the best way to fi nd out that something is going on. Plus, unlike most other gases, the generation rate of hydrogen increases proportionally to fault severity. The more serious the problem, the more hydrogen is generated! This behaviour, coupled with the fact that hydrogen very rarely varies with load, makes it truly representative of the transformer status, at all times.

Carbon monoxide on the other hand, will vary with load. However, signifi cant increases of carbon monoxide may be indicative of excessive overheating of cellulose. CALISTO 2 independently measures carbon monoxide precisely and accurately thus allowing you to correlate this measurement with other key values like hot spot or oil temperature.

The Trojan Calisto portable system provides a highly effi cient transformer management protection method covering all oil fi lled assets.

Key communication features

Data can be downloaded directly onsite, or via GSM wireless or Ethernet. Fault alarms can be sent via a number of communication methods. Calisto Access software - is supplied free with each Trojan Calisto and is the interface for the Calisto dissolved Hydrogen, Carbon Monoxide and water in oil unit. It enables client confi guration of alarm limits and alarm relays, and moisture measurement method. Confi guring communication to the Calisto through various connection types and network topologies including:

RS232, RS485, UDP Ethernet, Modem or telephone line connection, TCP Ethernet (using a TCPRS485 converter), with options for Wireless, SEL, cell-phone texting of alarms, and cell-based web trending of data

Operating systems: Windows 95/98/2000/XP/Vista

General

Self contained, all hoses and equipment housed on the trailer unit

230 volt – 10 amp normal power supply required.

The Calisto Hydrogen remains permanently commissioned within the Trojan.

The Trojan Calisto has an oil leak collection sump with detection switches. Any oil volume over 0.5 litres collecting in the sump will automatically shut the system down and close the safety valves.

Energised open / spring closed safety valves at the transformer end of the oil hoses that automatically close on all fault alarms and loss of power, isolating the transformer and making safe.

The oil hoses have a secondary outer security hose and leak detection, in conjunction with pressure sensing for irregularities

Lockable, secure and fully weatherproof.

Maintenance - no general maintenance is required. Routine visual inspection and check is recommended after each transformer.

Warranty – Full twelve month warranty.

Manual: A full operating, safety and maintenance manual is supplied.

Training - Onsite, or as required.

Backup – 24 / 7 plus monitoring service

Documentation

- Model PDGA User Manual

- Download PDF(4KB)*

- Model PDGA Data Sheet

- Download PDF(4KB)*